Looking for local artisans and traditions, I found La Mundial boot factory in Quito, Ecuador. The new facility is a quintessential place where only top quality leather is used to custom-make hand-sown riding boots. You will typically find professional jockeys, equestrians and riders wearing La Mundial, but they also offer everyday fashion boots and shoes for those who want to enjoy a luxurious accessory.

In 1906, Don Francisco Rivas opened a small shop in Quito, Ecuador and began handcrafting custom boots for horse riding enthusiasts. He worked side-by-side with an Italian shoemaker who came to Ecuador to showcase techniques in constructing tall riding boots.

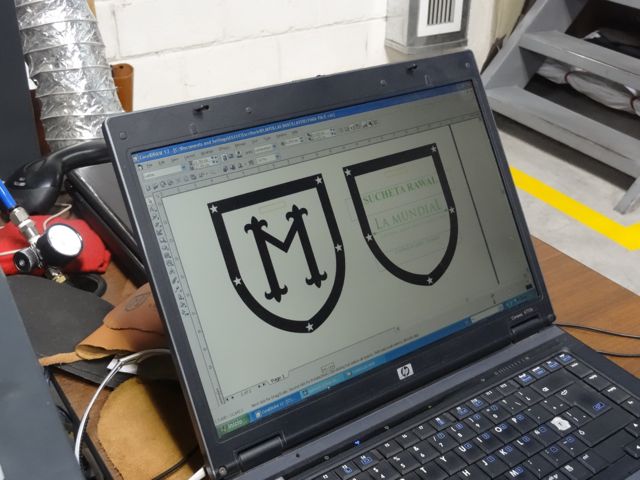

Today, La Mundial (meaning the world) has become an internationally recognized brand utilizing a local community of cobblers, latest technology and worldwide reach, while maintaing the 100 year old craft.

Here is the ten stop process the artists use to create these masterpieces.

1. When you express a desire to custom order a La Mundial boot, a local representative will be sent to you. He/she will take over 20 measurements of your foot, ankle, calf, and leg to get the most accurate dimensions to ensure superior fit.

2. Using your measurements and digital equipment, the will create a mold called “lasts,” of your leg. The prototype also has your specified patterns, colors and designs. The leather is imported from Italy, Argentina and around Ecuador. Colors include Cognac, Whiskey, Tobacco, Dark Chocolate, and of course, classic Black.

3. Next, leather is sent to the cutting table, and each component of the boot is cut with the utmost precision.

4. The cobbler carefully assembles the leg of each boot by joining together all the components required. The boot comes out of this step with the entire calf area constructed.

5. Now the leather is stretched and finishing touches are completed by hand to make sure the leather is smooth and fitted around the entire foot area.

6. To ensure durability and high quality, the soles and heels are made out of leather at the factory.

7. After the boot is assembled, they shape the soles to ensure the edges are finished to perfection.

8. Next, the boots are shaped around wooden trees (piernas de madera in Spanish) selected for the size and shape of your leg. Then they are heated to 110 degrees Fahrenheit, and immediately cooled to cure the leather and allow the boot to maintain its proper shape.

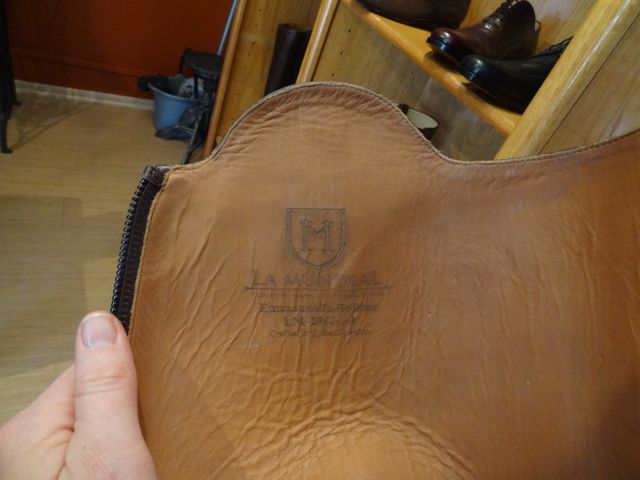

9. Polish, conditioning and finishing touches are added to every boot. They are even personalized with your name engraved on the inside.

10. The boots are placed in customized bags and shipped off to your destination. If you are unhappy with the product, need to refit or repair, just sent it back and they would take care of everything.

Want to get a pair of your own? Order them online or visit a horse show in your area. Check out their schedule. You can also visit the factory store in Quito, Ecuador by appointment only. It is open Monday-Friday from 9am-4:30pm. You can also book a guided tour to visit the factory through Tropic Journeys.

~ My visit to La Mundial was arranged by Tropic Journeys, an Ecuador based company specializing in responsible, community-based tourism that offers vacations in Ecuador Amazon, the Galapagos Islands, the high Andes and cloud forest.